PRODUCT

- Good tools are prerequisite to the successful execution of a job -

ABOUT US

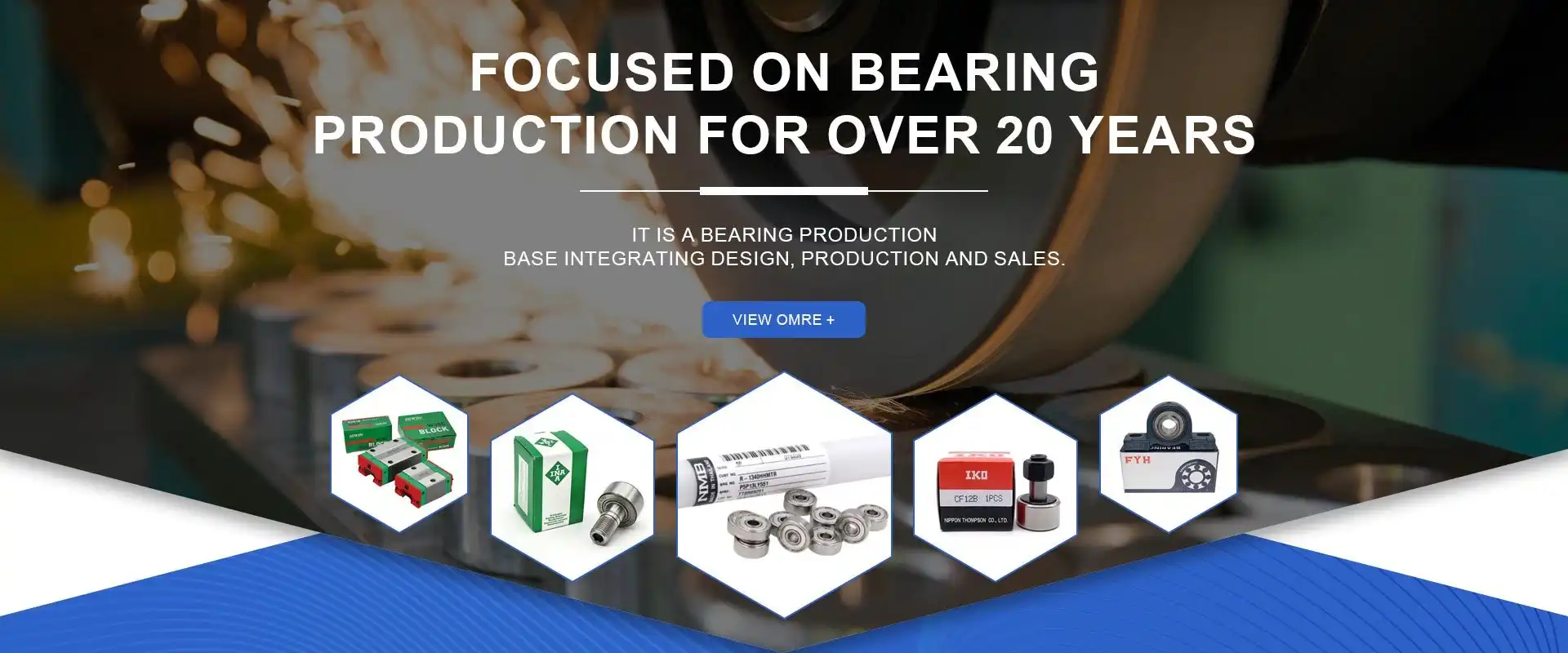

- A bearing production base that integrates design, production, and sales -

Founded in 2002

4000 specifications

Domestic users 800+

3 accuracy levels

Introduction to Shandong Delitong Bearing Co., Ltd

Shandong Delitong Bearing Co., Ltd., founded in 2002, is located in the industrial zone of Linqing, Shandong Province. It is a bearing production base integrating design, production and sales. The company has strong technical strength, complete measurement, physical and chemical inspection, and testing methods, strong product research and development capabilities, and technological innovation capabilities. It can design and produce bearings for various industries with 0, 2, 3, 6, 7, 8, 9, 7 types, 3 accuracy levels, and over 4000 specifications for various purposes. The products are widely used in industries such as metallurgy, shipbuilding, petroleum, chemical industry, mining, coal, hydropower,

BRAND

- The comprehensive quality of the product has reached the advanced level in China -

NEWS

- Real time information follows industry trends -

Characteristics of needle roller bearings

25 Oct,2022

Needle roller bearings are equipped with thin and long rollers (roller diameter D≤5mm, L/D≥2.5, L is the roller length), so the radial structure is compact, and its inner diameter size and load capacity are the same as other types of bearings. , the smallest outer diameter, especially suitable for support results with limited radial installation size. Depending on the application, a bearing without an inner ring or a needle roller and cage assembly can be selected. At this time, the journal surface and shell hole surface matching the bearing are directly used as the inner and outer rolling surfaces of the bearing to ensure the load capacity and operating performance. As with ring bearings, the hardness, machining accuracy and surface quality of the shaft or housing hole raceway surface should be similar to the raceway of the bearing ring. This kind of bearing can only bear radial load.

Installation of needle roller bearings

25 Oct,2022

Installation of full complement needle roller bearings is usually carried out using auxiliary sleeves. At this time, the auxiliary roller or auxiliary sleeve holds the needle roller to prevent it from falling out, and the journal lifts the needle roller with its own chamfer. As the needle roller bearing slowly moves inward on the journal, the auxiliary roller Or the auxiliary sleeve will be slowly withdrawn until it is installed in the working position.

25 Oct,2022

Single row angular contact ball bearings: machine tool spindles, high-frequency motors, gas turbines, centrifugal separators, small car front wheels, differential pinion shafts, booster pumps, drilling platforms, food machinery, dividing heads, repair welding machines, Low-noise cooling towers, electromechanical equipment, painting equipment, machine tool trough plates, arc welding machines

What are angular contact ball bearings?

25 Oct,2022

Single row angular contact ball bearings can only bear axial load in one direction. When bearing radial load, additional axial force will be caused. And it can only limit the axial displacement of the shaft or housing in one direction. Angular contact ball bearings have a contact angle of 40 degrees and therefore can withstand large axial loads. Angular contact ball bearings are a non-separable design, with shoulders of different heights on both sides of the inner and outer rings. In order to increase the load capacity of the bearing, the shoulder on one side will be machined lower so that more steel balls can be loaded into the bearing.

delitong@cndltbearing.com

delitong@cndltbearing.com

+86-18462269993

+86-18462269993 +86-18462269993

+86-18462269993